Can Cleanroom Doors Be Airtight Without Affecting Usability?

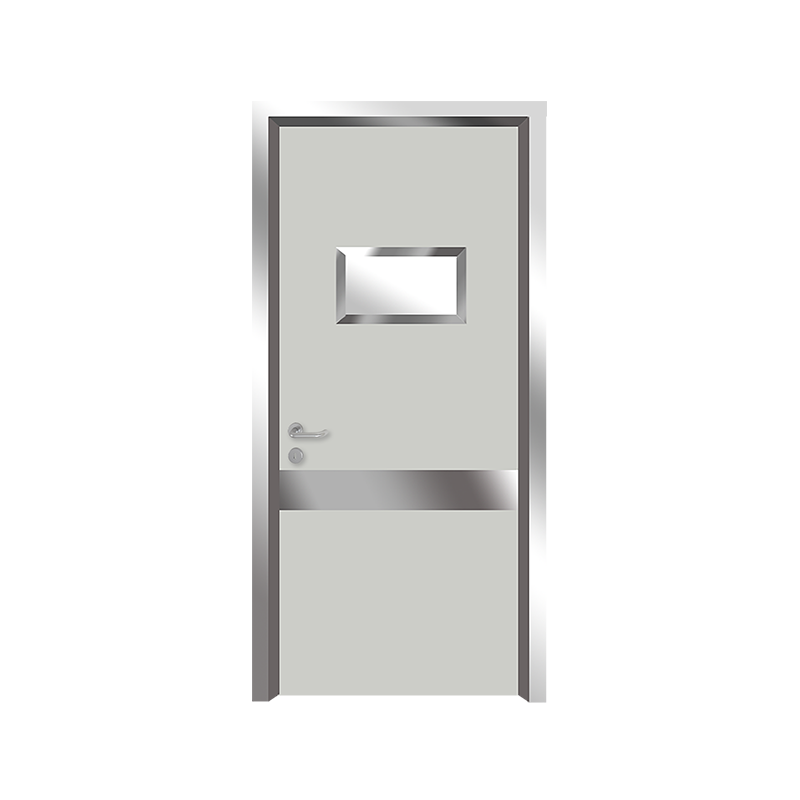

Cleanrooms are controlled environments designed to minimize contamination, maintain air quality, and protect sensitive processes in industries such as pharmaceuticals, electronics, biotechnology, and food manufacturing. One critical component of a cleanroom is the door. While cleanroom doors must maintain airtight seals to prevent contamination and preserve air pressure differentials, they must also remain practical and easy to use for personnel and equipment.

Understanding Airtight Cleanroom Door

Airtight cleanroom doors are designed to prevent particles, microbes, and airborne contaminants from passing between controlled spaces. They play a key role in maintaining positive or negative pressure differentials, which are essential for cleanroom classification and compliance with ISO or GMP standards.

Why Airtightness Matters

- Contamination control: Even minor leaks around doors can introduce particles, affecting sensitive processes.

- Pressure maintenance: Pressure differentials prevent cross-contamination between areas with different cleanliness levels.

- Energy efficiency: Airtight doors help maintain HVAC system efficiency by reducing air loss.

However, strict airtightness can sometimes make doors heavier, harder to operate, or slower to open, which can interfere with workflow and safety. Achieving a balance between airtightness and usability is therefore essential.

Design Considerations for Airtight Cleanroom Doors

Several design elements contribute to both airtightness and usability.

1. Door Type

- Swing doors: Common for low-traffic areas, they can be fitted with high-quality gaskets to maintain airtight seals. They are easy to operate but may require clearance space for opening.

- Sliding doors: Ideal for high-traffic areas and limited space, sliding doors can be equipped with automatic systems for hands-free operation. Proper seals along the edges are necessary to ensure airtightness.

- Pass-through doors: Used for transferring materials between rooms, they often include interlocking mechanisms to prevent both doors from opening simultaneously, preserving airtight integrity.

2. Materials

- Stainless steel: Resistant to corrosion and easy to disinfect, often used for high-grade cleanrooms.

- Aluminum: Lightweight and durable, aluminum doors can also support airtight sealing.

- Glass panels: Allow visibility without compromising airtightness when combined with proper gaskets and frames.

3. Sealing Mechanisms

- Gaskets and seals: High-quality silicone or EPDM gaskets can create airtight seals without excessive force.

- Magnetic seals: Provide consistent sealing along the door edge, ensuring airtightness while allowing smooth operation.

- Compression seals: Compress when the door closes to fill gaps, balancing airtightness with usability.

Automation and Usability

Manual doors, even when well-sealed, can become cumbersome if they are too tight or heavy. Automated doors improve usability while maintaining airtightness.

Benefits of Automation

- Hands-free operation: Reduces contamination risk by minimizing physical contact.

- Consistent closure: Ensures airtight seals every time the door closes.

- Adjustable speed: Modern systems allow doors to open and close at safe speeds for users and equipment.

- Safety features: Sensors prevent doors from closing on personnel or carts, combining usability with protection.

Maintaining Airtightness Without Sacrificing Efficiency

Airtight cleanroom doors must be regularly inspected and maintained to ensure usability and performance.

Maintenance Tips

- Inspect seals regularly: Look for wear, cracks, or gaps in gaskets. Replace as needed.

- Lubricate moving parts: Sliding and hinge mechanisms should operate smoothly without resistance.

- Test pressure differentials: Routine checks ensure doors are maintaining the cleanroom’s required pressure levels.

- Adjust automation systems: Ensure doors are calibrated to close fully without excessive force.

Proper maintenance keeps doors airtight while allowing smooth, effortless operation for users.

Real-World Examples

- Pharmaceutical cleanrooms: Sliding doors with magnetic seals and automatic sensors are commonly used to ensure airtight conditions while facilitating rapid movement of staff and equipment.

- Semiconductor manufacturing: Glass-panel doors with high-quality gaskets provide visibility and airtight seals, ensuring sensitive processes remain uncontaminated.

- Hospital isolation rooms: Automated swing doors maintain negative pressure without making the doors difficult to operate for medical staff.

Challenges and Solutions

Challenge 1: Balancing Airtightness and Weight

- Solution: Use lightweight materials like aluminum or composite panels combined with flexible gaskets to reduce operational strain.

Challenge 2: High Traffic Areas

- Solution: Install automated sliding doors with interlocks, ensuring continuous airflow control while supporting frequent use.

Challenge 3: Wear and Tear

- Solution: Schedule regular maintenance, replace worn gaskets promptly, and use durable seal materials designed for cleanroom conditions.

Conclusion

Cleanroom doors can indeed be airtight without affecting usability, provided careful attention is given to design, materials, sealing mechanisms, automation, and maintenance. Modern cleanroom doors combine high-performance seals, lightweight construction, and automated operation to achieve both airtightness and ease of use. Regular inspection and calibration are essential to ensure long-term performance, safety, and compliance with industry standards. By investing in the right door solutions, cleanrooms can maintain their contamination control goals while ensuring smooth, efficient workflow for personnel and equipment.

English

English Español

Español русский

русский عربى

عربى