Are Jiangyin Yatai Purification Equipment Technology Co., Ltd.'s High Speed Roll up Doors resistant to impact, scratches, and abrasion?

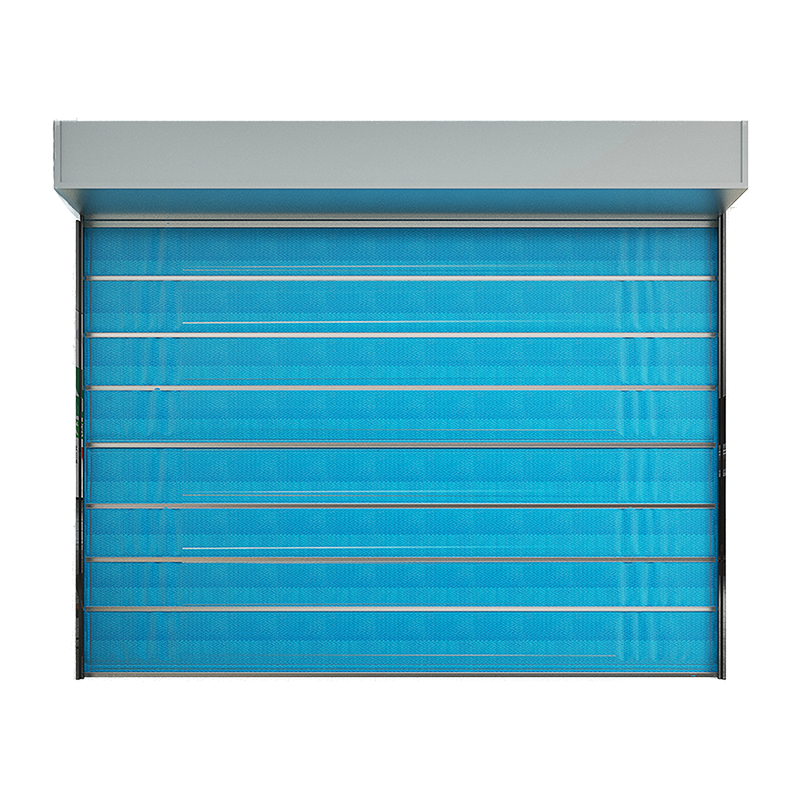

In the dynamic landscape of modern industrial and clean environment applications, High Speed Roll Up Doors for Cleanroom have emerged as pivotal components. Jiangyin Yatai Purification Equipment Technology Co., Ltd., nestled in the industrially vibrant Jiangyin City of Jiangsu Province on the south bank of the Yangtze River within the core of the Yangtze River Delta, has been making significant inroads in this domain. The company has established a comprehensive ecosystem, encompassing R & D, design, manufacturing, and sales, catering to the exacting needs of industries such as pharmaceuticals, electronics, biology, food, and hospital operating rooms, which demand sterile and dust - free environments.

The Significance of Impact, Scratch, and Abrasion Resistance in High Speed roll up Doors

In Industrial Settings

In industrial facilities, Rapid Roll Up Door is often installed in areas with high traffic, such as loading docks where forklifts and trucks frequently pass through. Impact resistance is crucial here. A door that can withstand the occasional collision from a forklift or a reversing truck without significant damage ensures the seamless flow of operations. Any door damage could lead to costly downtime for repairs, disrupt the supply chain, and pose safety risks to workers.

Scratch resistance is also vital. Industrial environments are rife with abrasive materials, and scratches on the door surface not only mar the aesthetics but can also act as initiation points for corrosion, especially in doors made of metal or metal - composite materials. Abrasion resistance, on the other hand, is essential as the constant opening and closing of the door, along with the friction caused by the movement of goods or equipment nearby, can gradually wear down the door materials over time. A door with poor abrasion resistance will have a shorter lifespan and require more frequent replacements.

In Clean Environments

For clean environments like pharmaceutical manufacturing plants and hospital operating rooms, the requirements are even more stringent. In these settings, maintaining a sterile and dust - free atmosphere is non - negotiable. Impact - resistant doors prevent any structural damage that could potentially release particles into the cleanroom. Even a minor impact - induced crack in the door could become a source of contamination, jeopardizing the integrity of the entire production or treatment process.

Scratch - free surfaces are equally important. Scratches can trap dust, bacteria, and other contaminants, making the door difficult to clean and sanitize effectively. In cleanroom environments, where every surface must be easily cleanable to meet strict hygiene standards, a scratch - resistant door is a must - have. Abrasion resistance ensures that the door can maintain its airtight and particle - tight seal over an extended period. As the door opens and closes thousands of times, an abrasion - prone door may start to develop gaps or leaks, allowing unwanted air and particles to enter the cleanroom.

Jiangyin Yatai's Clean Room Rapid Roll Up Door: Material Composition and Design for Durability

Material Selection

Jiangyin Yatai Purification Equipment Technology Co., Ltd. places great emphasis on material selection for its high speed roll up doors. For the door curtain, which is the most exposed part of the door, the company often utilizes high - quality materials. In many of their models, a specialized PVC - coated fabric is employed. This fabric is engineered to have a high tensile strength, which is a fundamental property for impact resistance. The PVC coating not only adds to the strength but also provides a smooth and durable surface that is highly resistant to scratches.

Some of their high - end models incorporate additional reinforcement elements such as aluminum alloy slats or fiberglass meshes within the fabric. These reinforcements act as a buffer against impacts, distributing the force over a larger area and preventing punctures or tears. The aluminum alloy slats, for example, are lightweight yet incredibly strong, capable of withstanding significant impact forces without deforming permanently.

In terms of the door frame and guide rails, Jiangyin Yatai typically uses robust metal alloys, such as stainless steel or high - grade aluminum. Stainless steel is renowned for its corrosion resistance, which is an added advantage in environments where moisture or chemical exposure may be a concern. The use of these materials in the frame and guide rails ensures that the door can withstand the mechanical stresses associated with high - speed operation and repeated impacts over an extended period.

Design Features

The design of Jiangyin Yatai's high speed roll up doors is also optimized for impact, scratch, and abrasion resistance. The door curtain is designed to roll up and down smoothly within the guide rails, minimizing friction and thus reducing the risk of abrasion. The guide rails are precision - engineered to ensure a snug fit for the door curtain, preventing any lateral movement that could cause the curtain to rub against the sides and get scratched.

In addition, the company incorporates anti - impact features in the door design. For example, some models are equipped with shock - absorbing bumpers at the bottom of the door. These bumpers are made of a resilient material, such as high - density rubber, which can absorb the energy of an impact when the door is hit. This not only protects the door itself but also reduces the force transmitted to the surrounding structure.

Another notable design aspect is the use of rounded edges and smooth surfaces throughout the door components. Sharp edges can be easily scratched or damaged, and they can also pose a safety hazard. By opting for rounded edges, Jiangyin Yatai's doors are less likely to get scratched during normal operation, and they also present a more user - friendly and safe profile.

Testing and Quality Assurance

In - House Testing Protocols

Jiangyin Yatai Purification Equipment Technology Co., Ltd. has an elaborate in - house testing facility to ensure that their high speed roll up doors meet the highest standards of impact, scratch, and abrasion resistance. The company conducts a series of rigorous tests on every door model before it is released into the market.

For impact testing, they use specialized equipment that simulates real - world scenarios. This may involve launching weighted projectiles at the door curtain at different speeds and angles to assess its ability to withstand impacts. The door is also subjected to repeated impact tests to evaluate its long - term durability under continuous stress.

Scratch resistance testing is carried out using abrasive materials of varying grit sizes. The door surface is rubbed with these materials under controlled conditions, and the resulting scratches are analyzed using high - magnification microscopes. The company sets strict criteria for the maximum allowable scratch depth and length, and any door that fails to meet these criteria is not approved for production.

Abrasion testing is equally comprehensive. The door curtain is made to undergo thousands of cycles of simulated opening and closing, with various weights and friction - inducing elements applied to replicate real - life usage. The wear and tear on the door curtain, frame, and guide rails are closely monitored, and if any signs of excessive abrasion are detected, the design or materials are re - evaluated and improved.

Third - Party Certifications and Industry Recognition

In addition to in - house testing, Jiangyin Yatai actively pursues third - party certifications to validate the performance of their high speed roll up doors. The company has passed the ISO9001 quality certification system, which is a testament to its commitment to quality management across all aspects of its operations, including product design, manufacturing, and testing.

Furthermore, the company has obtained a number of practical patents related to the design and functionality of its doors. These patents not only showcase the company's innovative approach but also indicate that their products have unique features that contribute to enhanced impact, scratch, and abrasion resistance.

Jiangyin Yatai's high speed roll up doors have also received industry recognition in the form of various honorary certificates. These accolades from industry associations and regulatory bodies further attest to the superior quality and durability of their products.

Real - World Applications and Customer Testimonials

Case Studies in Industrial Applications

In an industrial warehouse setting, Jiangyin Yatai's high speed roll up doors have been installed at the loading docks. Over a period of several years, these doors have withstood numerous impacts from forklifts and trucks. Despite the frequent traffic, the door curtains show minimal signs of wear and tear. The impact - resistant design, with its shock - absorbing bumpers and reinforced curtain materials, has ensured that the doors continue to function smoothly, with no disruptions to the daily operations of the warehouse.

In a manufacturing plant that produces heavy machinery, the high speed roll up doors are used to separate different production areas. The doors' scratch - resistant surfaces have remained unscathed, even though the area is filled with abrasive materials such as metal shavings. The employees at the plant have reported that the doors are easy to clean and maintain, thanks to their smooth surfaces, which do not trap dirt or debris.

Success Stories in Clean Environments

In a pharmaceutical manufacturing facility, the installation of Jiangyin Yatai's high speed roll up doors has been a game - changer. The doors' ability to maintain a sterile environment has been crucial. The impact - resistant design has prevented any damage that could lead to contamination, and the scratch - and abrasion - resistant surfaces have made cleaning and sanitization a breeze. The facility has reported a significant reduction in the number of environmental monitoring failures since the installation of these doors.

In a hospital operating room, the high speed roll up doors from Jiangyin Yatai have been well - received. The doors' airtight and particle - tight seals, maintained by their abrasion - resistant construction, have helped in creating a pristine environment for surgical procedures. Surgeons and nursing staff have praised the doors for their durability and ease of operation, which is essential in a high - stress medical environment.

Customer testimonials also speak volumes about the performance of Jiangyin Yatai's high speed roll up doors. Many customers have commended the company for its commitment to quality and its ability to deliver doors that meet their exacting requirements. They have reported that the doors not only offer excellent resistance to impact, scratches, and abrasion but also provide long - term reliability and low maintenance costs.

In conclusion, Jiangyin Yatai Purification Equipment Technology Co., Ltd.'s high speed roll up doors are engineered with a meticulous focus on impact, scratch, and abrasion resistance. Through careful material selection, innovative design features, rigorous testing protocols, and positive real - world applications, these doors have proven to be a reliable and durable solution for a wide range of industrial and clean environment applications. Whether it's withstanding the rigors of a busy industrial facility or maintaining the sterile conditions of a cleanroom, Jiangyin Yatai's high speed roll up doors are up to the task, making them a top choice for businesses seeking high - quality door solutions.

English

English Español

Español русский

русский عربى

عربى