Cleanroom Door Hardware Accessories ensure door sealing and stable operation

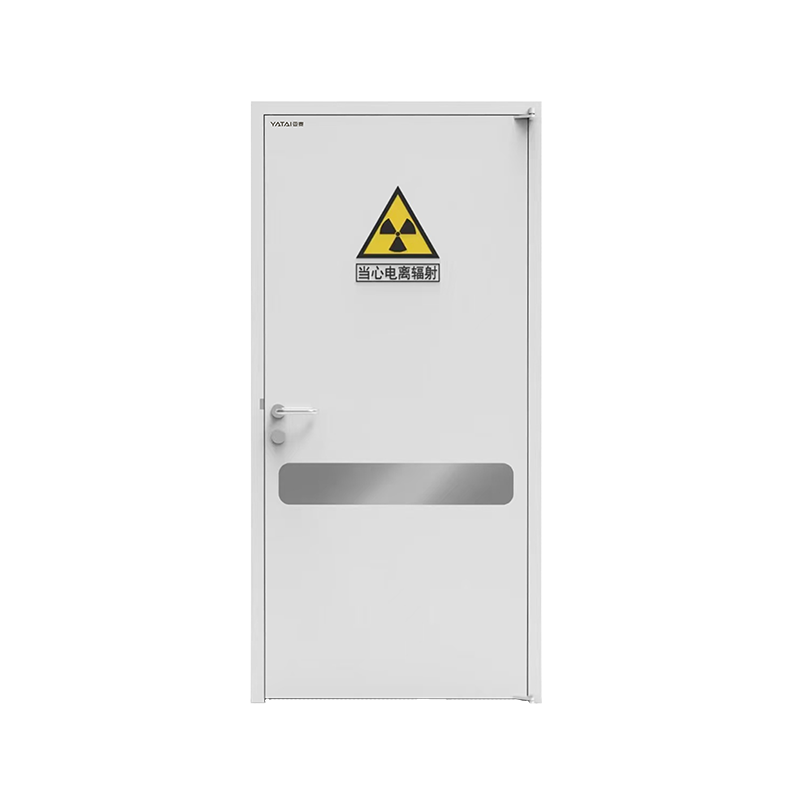

In the highly controlled environments of cleanrooms—such as pharmaceutical manufacturing facilities, biotechnology laboratories, semiconductor production lines, food processing plants, and hospital operating rooms—every component must contribute to maintaining sterility, minimizing particle generation, and ensuring operational reliability. While the door panel and frame are critical, it is often the cleanroom door hardware accessories that determine the overall performance, longevity, and effectiveness of the door system. Jiangyin Yatai Purification Equipment Technology Co., Ltd., a leading manufacturer based in Jiangyin City, Jiangsu Province, recognizes the pivotal role of high-quality hardware in cleanroom integrity and has developed a comprehensive range of precision-engineered accessories that ensure superior door sealing and stable operation.

Located on the south bank of the Yangtze River in the core area of the Yangtze River Delta, Jiangyin Yatai Purification Equipment Technology Co., Ltd. is a professional enterprise specializing in the research, design, manufacturing, and sales of high-performance cleanroom doors, windows, and related purification equipment. The company’s product portfolio includes the YT clean door and window series, steel doors, melamine doors, automatic closed doors, medical doors, electric swing doors, aluminum alloy clean doors, fast rolling doors, fireproof insulation doors, and more. However, what truly sets Jiangyin Yatai apart is its holistic approach—designing not only the doors themselves but also integrating high-grade hardware accessories that are essential for optimal functionality.

The Critical Role of Hardware in Cleanroom Doors

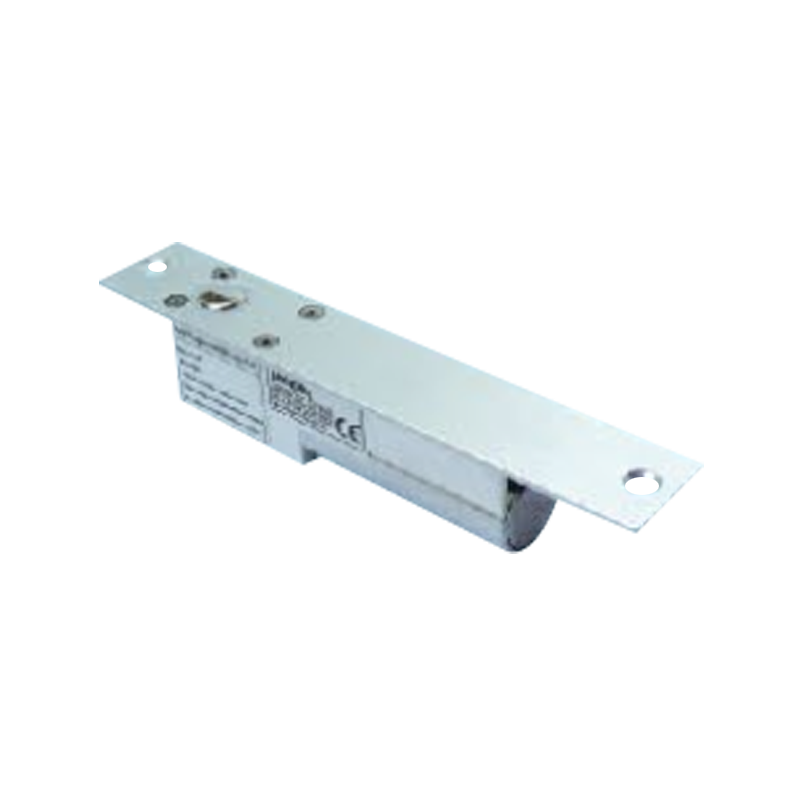

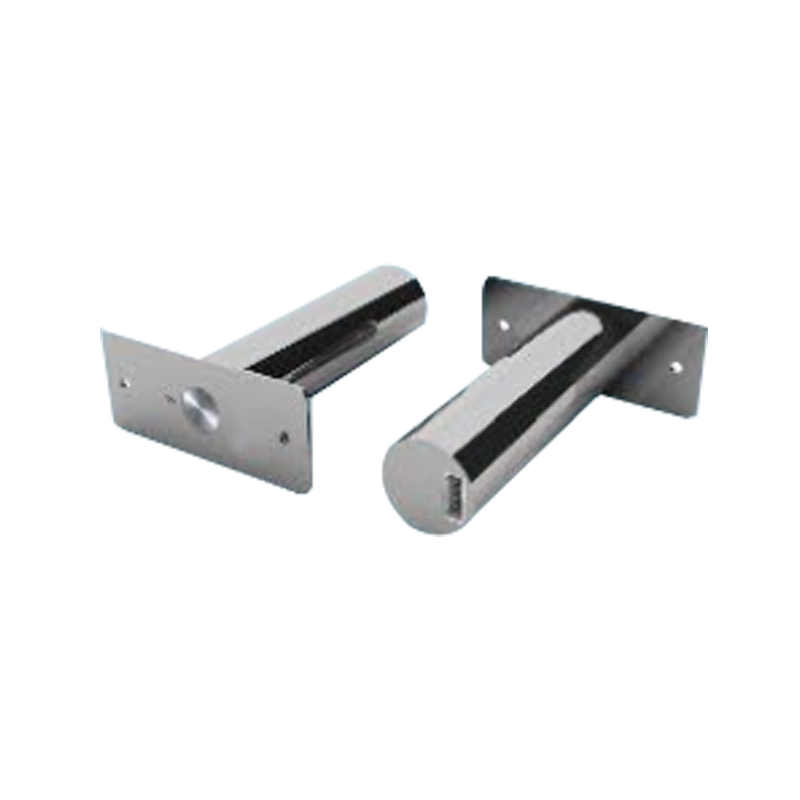

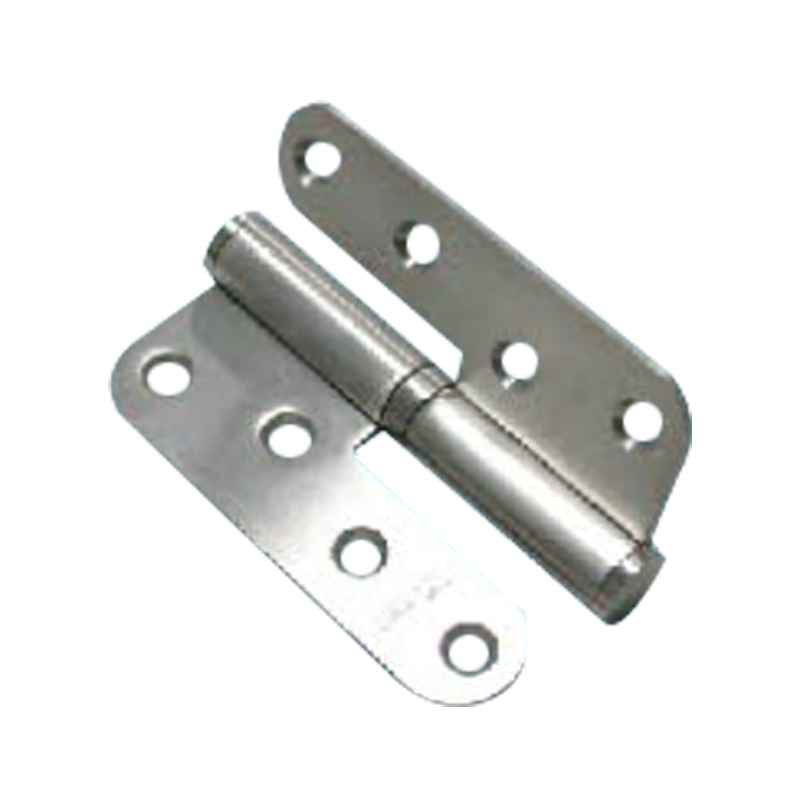

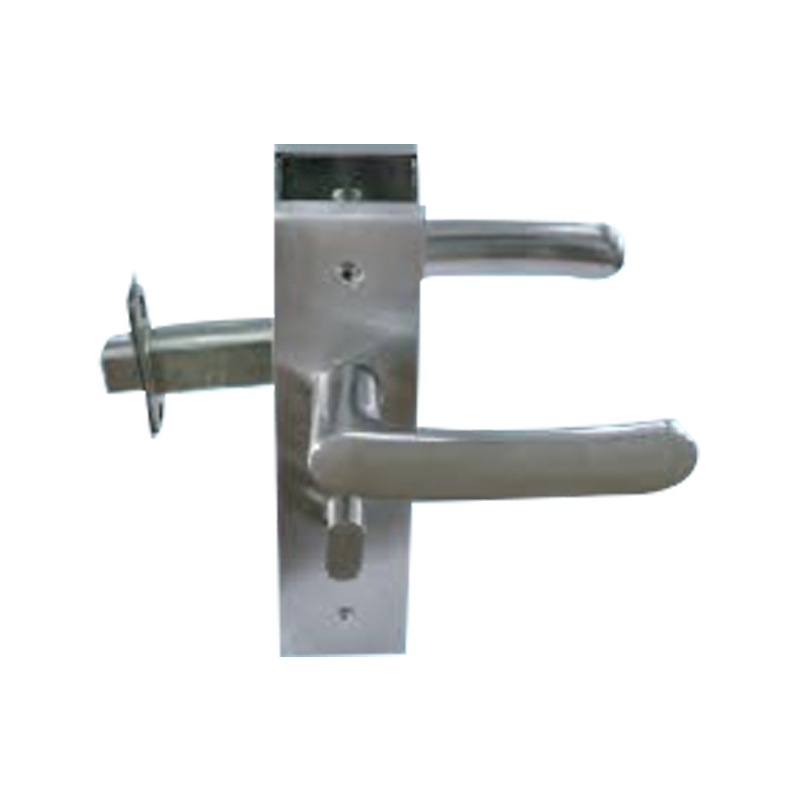

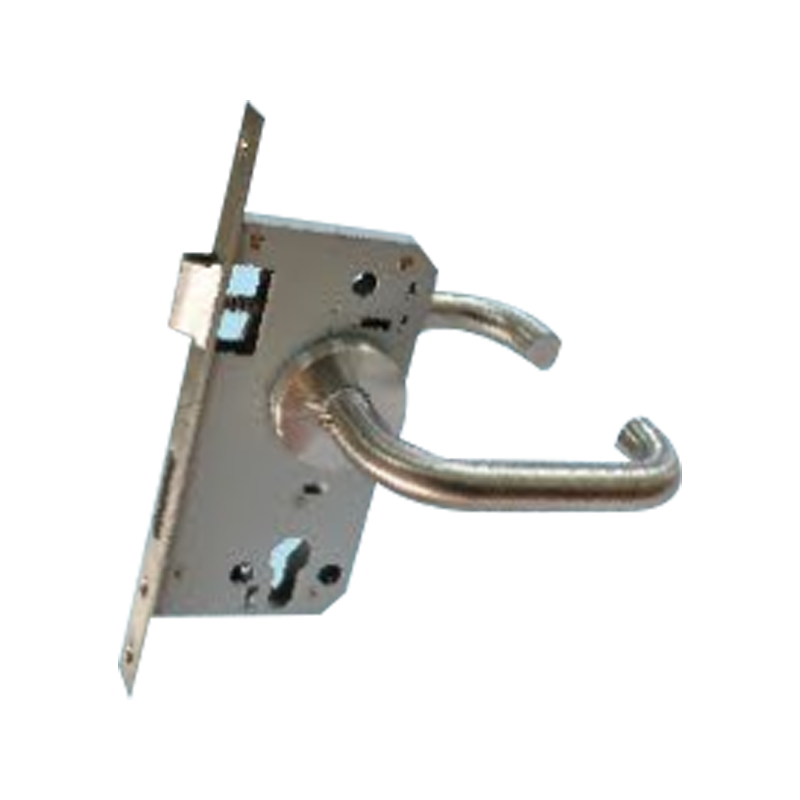

In a cleanroom, even the smallest gap or mechanical instability can compromise air pressure differentials, allow contaminant ingress, and disrupt laminar airflow. This is where Cleanroom Door Accessories become indispensable. These components—including hinges, seals, latches, closers, door stops, threshold systems, and locking mechanisms—are engineered to work in harmony with the door structure to provide airtight sealing, smooth operation, and long-term durability.

Jiangyin Yatai’s hardware accessories are manufactured using corrosion-resistant materials such as stainless steel, anodized aluminum, and high-resilience polymers, ensuring compatibility with frequent cleaning, disinfection, and high-humidity environments. The company’s R&D team focuses on minimizing particle shedding and electrostatic buildup, making the hardware ideal for ISO Class 5 (Grade A) and higher cleanroom standards.

Precision Sealing for Contamination Control

One of the primary functions of cleanroom door hardware is to support effective sealing. Jiangyin Yatai equips its doors with high-performance EPDM (ethylene propylene diene monomer) or silicone gaskets, integrated into specially designed compression seals and sweep bars. These seals are activated by precision latches and multi-point locking systems that ensure uniform pressure around the entire door perimeter, eliminating air leakage and preventing cross-contamination between zones.

The threshold systems are another key feature—designed to create a seamless barrier between rooms while allowing smooth passage for trolleys and equipment. Jiangyin Yatai’s automatic door models are fitted with sensor-activated bottom seals that deploy when the door closes, enhancing airtightness without hindering accessibility.

Stable Operation Through Advanced Hardware Design

Stable, smooth, and quiet operation is essential in high-traffic cleanroom environments. Jiangyin Yatai uses heavy-duty, self-lubricating hinges with minimal tolerance to prevent sagging or misalignment over time. For automatic and electric swing doors, the company integrates high-torque closers and soft-close mechanisms that ensure controlled, consistent movement—reducing wear and preventing slamming, which could disturb sensitive processes or generate particles.

For sliding and fast-rolling doors, linear guide rails and precision rollers are used to ensure frictionless movement, even under continuous operation. These hardware components are rigorously tested for over 100,000 cycles, guaranteeing long-term reliability in demanding industrial settings.

Complete System Integration and Quality Assurance

Jiangyin Yatai operates a fully integrated R&D, design, manufacturing, and sales system, allowing for seamless coordination between door design and hardware integration. This vertical control ensures that every accessory is perfectly matched to the door model, eliminating compatibility issues and enhancing overall system performance.

The company has achieved ISO9001 quality management system certification, affirming its commitment to consistent quality and customer satisfaction. Additionally, Jiangyin Yatai has obtained multiple proprietary technology patents and industry honors, particularly in the fields of sealing technology and automatic door control systems.

Applications Across Industries

Jiangyin Yatai’s cleanroom door hardware accessories are widely used in pharmaceutical cleanrooms where GMP compliance is mandatory, in hospital operating rooms requiring infection control, and in electronic manufacturing facilities where electrostatic discharge (ESD) protection is critical. The hardware is also suitable for food production environments, where hygiene and washdown resistance are paramount.

While cleanroom doors are often evaluated based on their appearance or material composition, it is the hardware accessories that ultimately determine their sealing performance, operational stability, and service life. Jiangyin Yatai Purification Equipment Technology Co., Ltd. understands this critical balance and delivers a complete, high-performance door system—where every hinge, seal, and latch is engineered to perfection. By focusing on precision, durability, and contamination control, Jiangyin Yatai ensures that its cleanroom doors not only meet but exceed the demands of the most stringent environments. For industries where cleanliness is non-negotiable, the right hardware makes all the difference—and Jiangyin Yatai provides the solution.

English

English Español

Español русский

русский عربى

عربى