Are the surfaces of Jiangyin Yatai Purification Equipment Technology Co., Ltd.'s HPL Cleanroom Doors resistant to chemicals, solvents, and disinfectants?

In the realm of cleanroom technology, the integrity of every component is of paramount importance. Among these, cleanroom doors play a pivotal role in maintaining the controlled environment. Jiangyin Yatai Purification Equipment Technology Co., Ltd., located in the strategic locale of Jiangyin City, Jiangsu Province, on the south bank of the Yangtze River and within the bustling core of the Yangtze River Delta, has emerged as a key player in the production of Cleanroom High Pressure Laminate Doors.

Company Overview

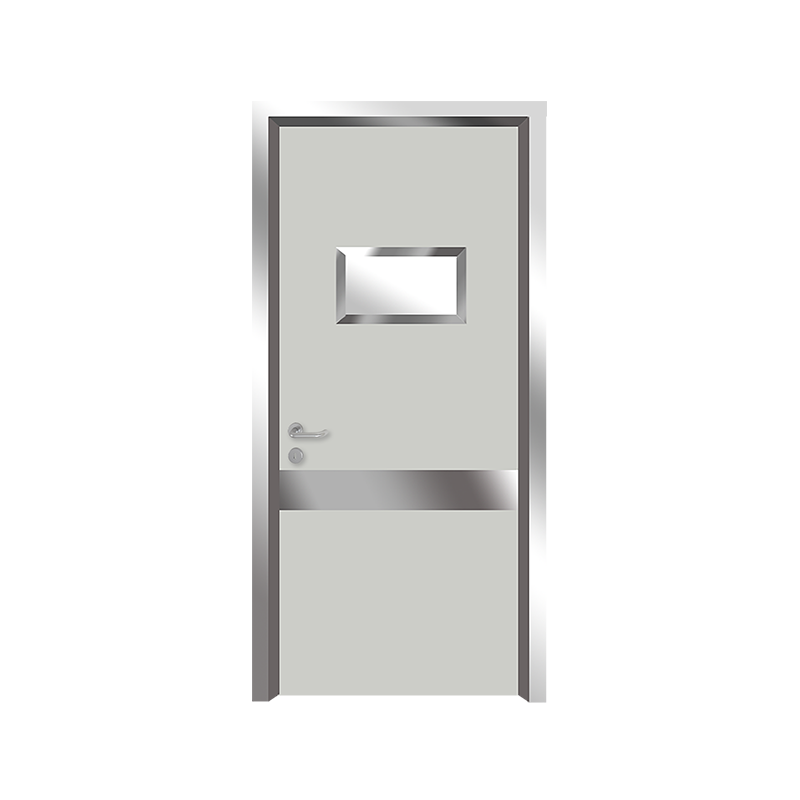

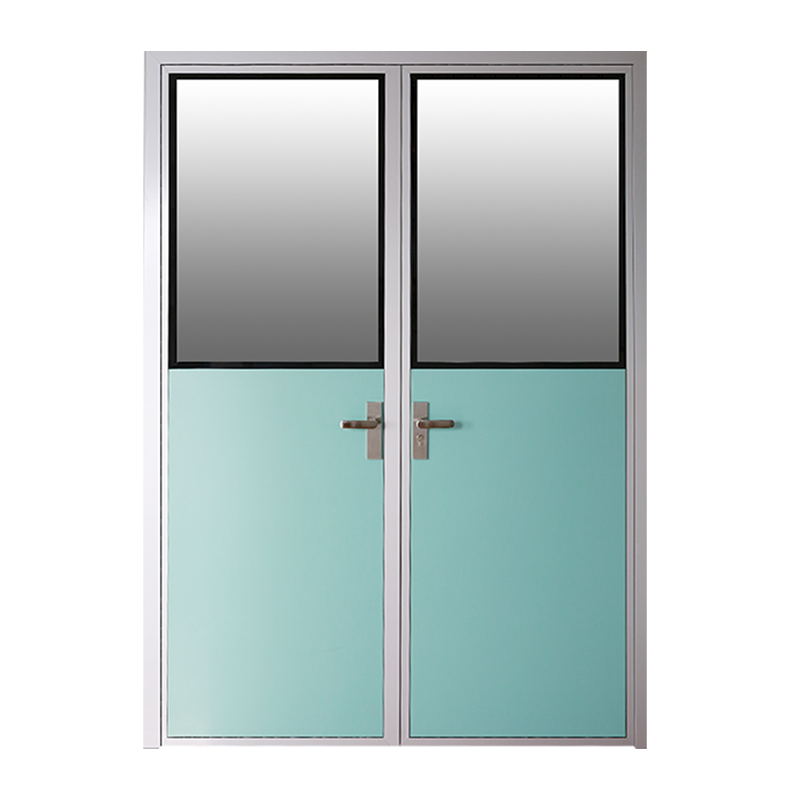

Jiangyin Yatai Purification Equipment Technology Co., Ltd. has established itself as a comprehensive entity with a complete R & D, design, manufacturing, and sales system. The company specializes in catering to the stringent needs of sterile and dust - free workshops across a wide spectrum of industries, including pharmaceuticals, electronics, biology, food, and hospital operating rooms. Their product portfolio is extensive, ranging from various types of YT clean door and window series, steel doors, melamine doors, to clean windows, ward doors, and an array of specialized doors such as automatic closed doors, anti - collision doors, medical doors, electric swing doors, clean doors, aluminum alloy clean doors, fast rolling doors, and insulation and fireproof clean doors.

With its own well - equipped production workshops and warehouses, outfitted with state - of - the - art production and quality inspection equipment, the company ensures that each product leaving its facility meets the highest standards. Additionally, having passed the ISO9001 quality certification system and amassing a number of practical patents and honorary certificates, Jiangyin Yatai stands as a testament to quality and innovation in the purification equipment domain.

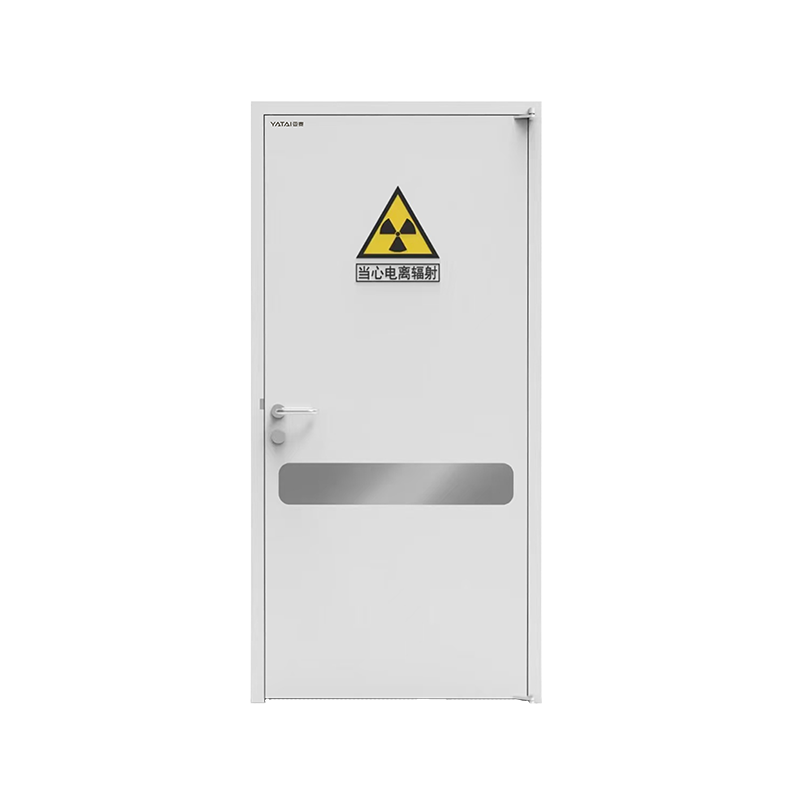

High - Pressure Laminate (HPL) Cleanroom Doors

One of the company's notable offerings is the High - Pressure Laminate (HPL) Cleanroom Doors. HPL is a composite material that has gained significant traction in cleanroom applications due to its unique properties. But the question that often looms large for industries using these doors is their resistance to chemicals, solvents, and disinfectants.

Chemical Resistance

In industries such as pharmaceuticals and electronics, exposure to a plethora of chemicals is inevitable. For instance, in pharmaceutical manufacturing, chemicals are used in the production process, for equipment cleaning, and in maintaining the sterile environment. Jiangyin Yatai's Purification Door is engineered with materials that exhibit remarkable chemical resistance. The HPL surface is formulated in a way that it can withstand contact with a wide range of common chemicals found in these industries.

The company's R & D team has conducted rigorous tests using chemicals like acids, bases, and organic solvents that are prevalent in cleanroom operations. Results have shown that the HPL surface does not corrode, discolor, or degrade upon exposure to these chemicals. This is crucial as any chemical - induced damage to the door surface could compromise the integrity of the cleanroom, leading to potential contamination risks.

Solvent Resistance

Solvents are frequently used for cleaning and degreasing in cleanroom environments. In the electronics industry, solvents are used to clean circuit boards and other sensitive components. Jiangyin Yatai's Pharmaceutical Cleanroom Doors are designed to resist the effects of these solvents. The high - pressure lamination process used in manufacturing the doors creates a dense and non - porous surface. This non - porosity prevents solvents from penetrating the door material, thus ensuring that the door's structural and aesthetic integrity remains intact.

Even after repeated exposure to solvents such as acetone, isopropyl alcohol, and various chlorinated solvents, the HPL surface shows no signs of swelling, softening, or delamination. This solvent resistance not only extends the lifespan of the doors but also reduces the need for frequent replacements, leading to cost - savings for businesses.

Disinfectant Resistance

In cleanroom environments, especially in healthcare and pharmaceutical settings, regular disinfection is a non - negotiable requirement. Disinfectants are used to kill bacteria, viruses, and other microorganisms that could potentially contaminate the area. The types of disinfectants used can range from alcohol - based solutions to more potent chemical disinfectants.

Jiangyin Yatai's HPL cleanroom doors are highly resistant to these disinfectants. The company's doors have been tested against common disinfectants such as 75% ethanol, 0.1% new benzyl alcohol solution, 0.2% new benzyl alcohol solution, 0.5% chlorhexidine acetate solution, and 0.1% chlorhexidine acetate solution. These tests simulate the real - world conditions of cleanroom disinfection procedures. The HPL surface not only withstands the chemical action of these disinfectants but also maintains its smooth and easy - to - clean surface finish. This is essential as a rough or damaged surface could harbor microorganisms, defeating the purpose of disinfection.

Moreover, the antibacterial properties of the HPL material itself contribute to the overall effectiveness of disinfection. Microorganisms find it difficult to adhere to the non - porous HPL surface, and the disinfectants can easily reach and eliminate any potential contaminants.

Conclusion

Jiangyin Yatai Purification Equipment Technology Co., Ltd.'s HPL cleanroom doors are a paragon of excellence when it comes to resistance to chemicals, solvents, and disinfectants. The company's commitment to quality, evident from its comprehensive production system, state - of - the - art facilities, and numerous certifications, is reflected in the performance of its products.

For industries that operate in cleanroom environments where the use of chemicals, solvents, and disinfectants is an integral part of daily operations, Jiangyin Yatai's HPL cleanroom doors offer a reliable and durable solution. By investing in these doors, businesses can ensure the long - term integrity of their cleanroom environments, minimize the risk of contamination, and ultimately, enhance the quality and safety of their products and operations.

In an era where the demand for cleanroom technology is constantly evolving, Jiangyin Yatai stands at the forefront, ready to meet the challenges and exceed the expectations of its customers with its innovative and high - performing purification equipment.

English

English Español

Español русский

русский عربى

عربى